--Environmental Monitoring Solutions

Monitor what matters. Act before it's a problem.

Real-time air quality sensing, filter pressure monitoring, and dust bin level tracking. Know when conditions change—and respond before small issues become big problems.

| 24/7 |

CONTINUOUS MONITORING

| PM1.0 |

PARTICULATE SENSING

| <10s |

ALERT RESPONSE

THE CHALLENGE

You can't manage what you can't measure.

Whether it's particulates in the air, pressure drops across filters, or a full dust bin, invisible problems become expensive—or dangerous—fast.

Invisible Air Hazards

PM1.0 particles are invisible but deadly. They bypass your body's defenses and lodge deep in lung tissue. By the time you smell dust or fumes, exposure has already occurred.

Clogged Filters Go Unnoticed

A clogged dust collector filter doesn't announce itself—it just stops working effectively. Suction drops, dust escapes, and you don't know until there's a visible problem.

Dust Bin Overflow

When collection bins fill up unnoticed, dust backs up into the system—or worse, overflows onto the floor. Full bins are also a fire hazard in shops with combustible dust.

Guesswork Maintenance

Changing filters on a schedule wastes money if they're still good—but waiting too long risks system failure. Without real data, you're guessing at maintenance timing.

THE SOLUTION

Three sensors. Complete environmental awareness.

Monitor air quality, filter condition, and dust collection capacity with purpose-built sensors that work together through the GRIT platform.

AIR QUALITY MONITORING | AIR PRESSURE MONITORING | DUST BIN SENSOR

01.

Air Quality Monitoring

See what you're breathing. In real time.

Our SEN55-based air quality sensor measures PM1.0, PM2.5, and PM10 particulates continuously, plus temperature, humidity, and VOCs. Know exactly what's in the air—and when levels change.

- PM1.0, PM2.5, PM10 particulate measurement

- Temperature and relative humidity sensing

- VOC (volatile organic compound) detection

- Sampling every 10 seconds with rolling averages

- Calibrated for wood dust, metal particles, and shop contaminants

- Configurable alert thresholds with push notifications

02.

Air Pressure Monitoring

Know when filters need changing. Before they fail.

Our differential pressure sensor monitors the pressure drop across filters in dust collectors, paint booths, and exhaust systems. As filters clog, pressure rises—and the system alerts you before performance degrades or filters blow out.

- Differential pressure measurement across filter media

- Configurable alert thresholds for "attention needed" and "critical"

- Trend tracking shows filter degradation over time

- Replace filters based on actual condition, not guesswork

- Works with cartridge filters, bag filters, and panel filters

- Applicable to dust collectors, paint booths, and fume exhausts

03.

Dust Bin Sensor

Never overflow a dust bin again.

Our bin level sensor monitors how full your dust collection containers are in real time. Get alerts before bins overflow—avoiding mess, downtime, and the fire hazard of overfilled collection systems.

- Continuous bin fill level monitoring

- Works with drums and collection containers with lid-mounted sensor

- Dashboard and red strobe alert light show when bin is full

- Prevents overflow, mess, and potential fire hazards

ECOSYSTEM

Part of the complete GRIT platform.

Dust management integrates seamlessly with GRIT's full suite of workshop automation solutions—all managed from a single dashboard.

Whether you start with dust management or add it later, every GRIT component works together through our unified hub architecture.

Dust Management

Clean air isn't optional. It's essential.

Asset Management

Know where everything is. Always.

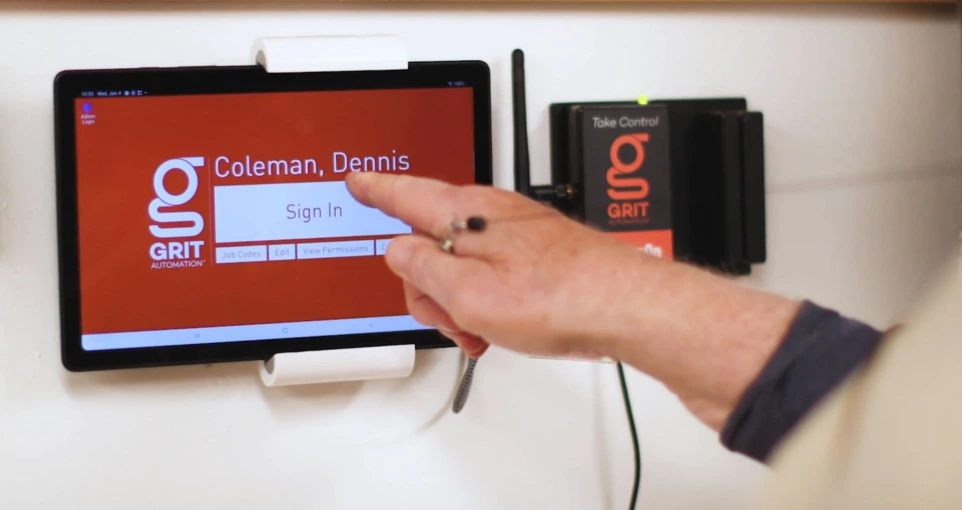

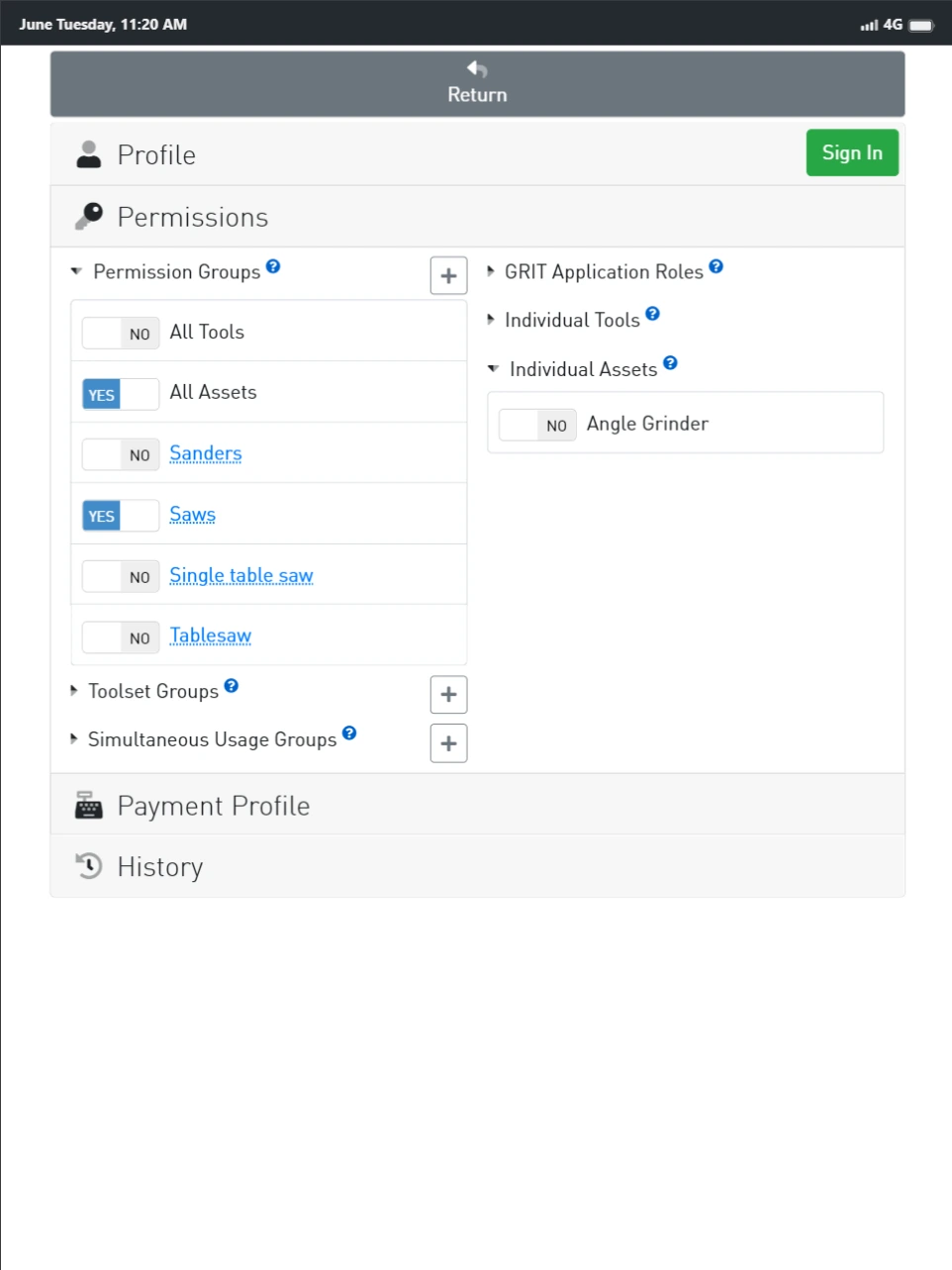

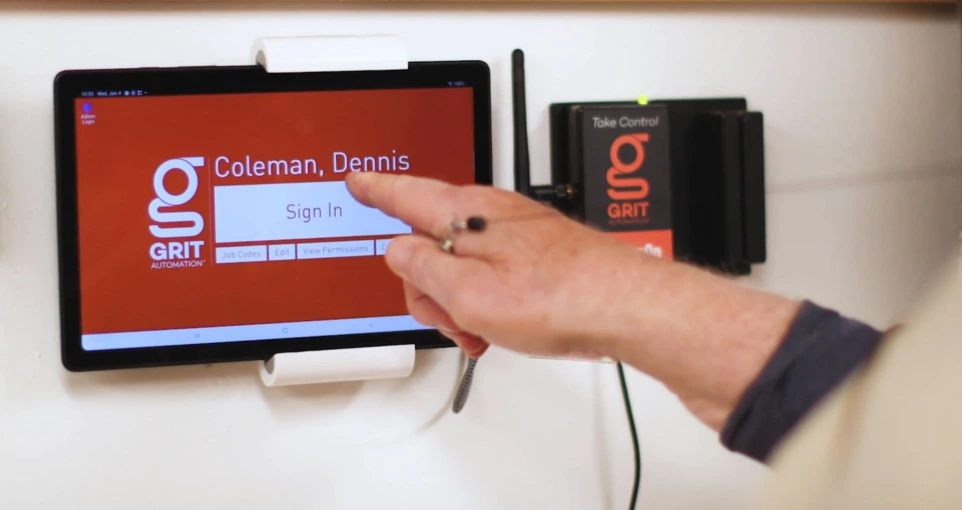

Access Control

Know who's using what. Every time.

Time Tracking & Door Access

Secure access to facilities and rooms, plus track hours for payroll.